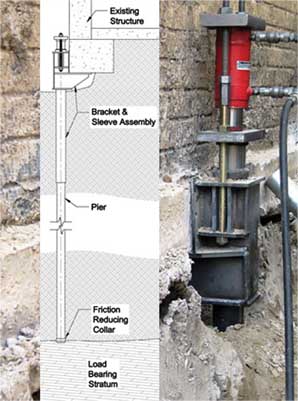

Pressure Piles

At that point, the structure either begins to lift or the target pressure/load is achieved. The weight of the structure is then transferred from the unstable soil, to the foundation brackets, through the piers, and to firm load bearing soil or bedrock.

Push Pier systems develop a factor of safety against pier settlement by the pier installation methods used and the sequence with which multiple piers are driven and then re-loaded. Piers are first driven individually using the maximum weight of the structure and any contributory soil load. After all of the piers are driven, the piers are re-loaded simultaneously, and the total reaction load is distributed over the multiple pier locations.

Typical factors of safety against pier settlement range from about 1.5 to 3.0, with higher values generally achieved for structures with greater rigidity.

Advantages of Push Piers

Push piers are one of the most frequently-installed piers, because installation is simple. Because the weight of the structure is used as the resistance to installing the pier, load testing is immediate and it is easy to determine the ability of the pier to hold up the weight of the structure. Another advantage is that no equipment is required for the pier installation. For structures with shallow footings, access holes for installation are generally dug by hand. In some cases, it is faster and less expensive to use a small excavator to dig the access holes, but the excavator is not required for driving the piers.

Disadvantages

Push piers are only as good as the structure that they’re installed under. Therefore, push piers aren’t a good choice when building loads are anticipated to increase, there is extensive cracking or deterioration of the foundation, or when the structure is so light that it doesn’t provide enough resistance to push the pier sufficiently into the ground. Most single story structures, particularly with short block walls, wood framing and siding, are too light to be sure push piers can be driven to an adequate depth. In these cases,helical piers are generally the most appropriate repair method.

Mammoth Helical installs steel piers, which are usually galvanized, given the geographic soils in the location of much of our service area. Eccentric push piers require a few feet of overhead clearance, so are typically not installed in crawl spaces.