Construction

Helical Piers: Endless Possibilities – Predictable Results

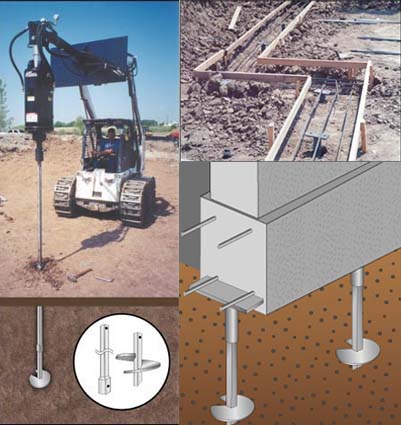

When encountering poor soil conditions on a building site it may be necessary to transfer the building loads to deeper more stable soils. Determining the most effective and economical solution to this problem will generally involve an investigation of the soil conditions which is typically done with a soil boring. A soil boring is performed to obtain data that provides the soil type, the organic layers and depth to bedrock. The Helical Pier Deep Foundation System is designed, tested and proven for applications in expansive soils, high water tables, fill areas and other areas where unstable soils require piering. A soil boring can help determine the proper depth for installing piles based on the information discovered within the soil boring report.

Once the soil conditions and load requirements are known, the size of the shaft along with the size and number of helixes are determined. Helical piles are steel shafts with helixes welded to them. The Helical pile is installed by screwing it into the ground. On reinforced footing or stem walls, the new construction of Pier Tech Piers are usually placed every 8 to 10 feet depending upon the load of the structure and the bearing strength of the soil.

ADVANTAGES

- Predictable results

- Holds design loads in specific soils

- Easy to store and transport

- Installs in any weather and in limited access areas

- No excavation spoils to remove

- Can be loaded immediately

Solar Energy

Using the patented Pier Tech Helical, a rock solid foundation is quickly and easily installed without tedious digging or excavation. Our complete solar ground system installs in hours instead of days and does not require curing. It provides the support to hold any size solar array.

Wind Energy

Helical piers are simplifying wind tower installation. By using a helical pier to support the tower and helical anchors to support the guide wire a secure tower can be raised concrete free without curing times.

Helical Anchors Gain Ground in Tilt-Up Concrete Construction

Tilt Up Construction

Tilt-up concrete offers many advantages: it’s a fast, efficient, and versatile construction method that can produce buildings both structurally sound and aesthetically sophisticated. During construction, however, tilt-up panels require bracing to keep them upright and stable until they can be connected to structural floor and roof diaphragms. Traditionally, the bracing has been connected to the interior side of the panels and anchored to the slab.